CO2 CARBON CAPTURE

Clean Fuels from CO2 Utilization

Ecotechnol has developed an economic process for capturing carbon dioxide from exhaust gases produced in the burning of a wide range of carbon based fuels including coal, oil, natural gas or biomass.

The process can be retrofitted to existing combustion processes, including power stations, furnaces, boilers, incinerators etc, and does not require high concentrations of CO2 in the exhaust gas. The process combines the concentrated CO2 with CH4 to produce clean fuels such as diesel, DME and Avgas.

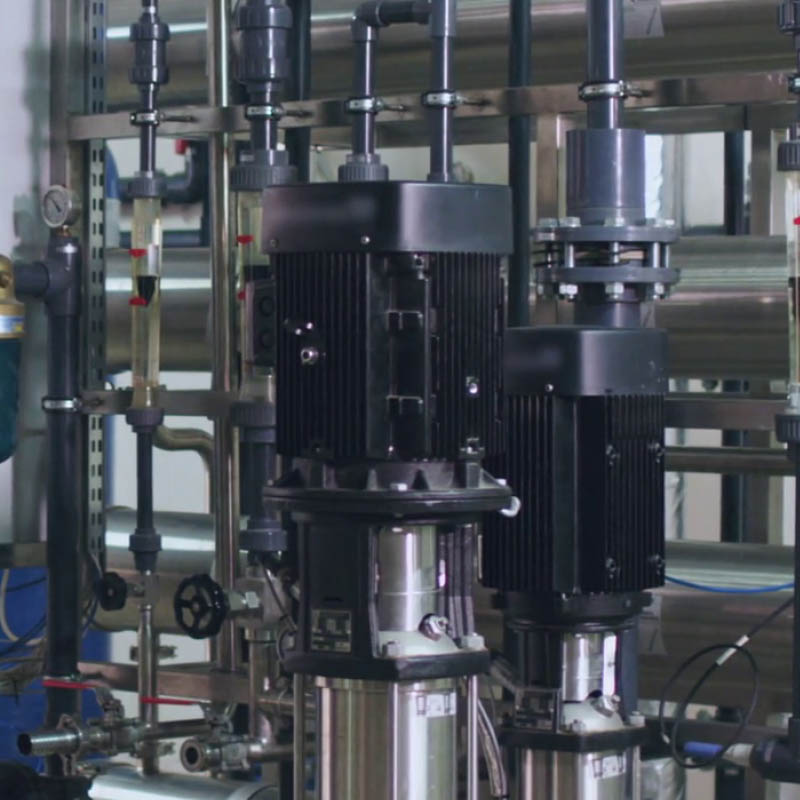

Ecotechnol’s membrane system

The Ecotechnol membrane system is compact and simple.

The membrane system can capture more than 90% of the CO2 in the flue/exhaust gas and concentrate it up to a volume of approximately 10% of the original feed gas volume.

Ecotechnol CO2 Capture Process Advantages

- Capital and operating costs are significantly lower than competing processes e.g. Amine Absorption

- No need to use chemicals or to regenerate or replace absorbents.

- Less energy consumption than competing processes

- Can be retrofitted to any existing power plant infrastructure

- Modular design allows scale-up using multi-stage operations

- Low maintenance because there are no moving parts in the membrane system

- No corrosion issues or complications related to chemical consumption or regeneration

- Compact and lightweight and can be positioned either horizontally or vertically, ideal for retrofitting to existing plants

Integrated Carbon Capture and Conversion to Clean Fuels CO2 Monetization Technology

Ecotechnol has developed an integrated process for the capture of carbon dioxide from industrial flue gas emissions and conversion for the economical production of clean fuels.

The patented process, utilises Green House Gases and highly politicized CO2 as a valuable feedstock rather than waste product.

This technology can be retrofitted existing Coal or Gas fired Gas power stations, LNG plants, Cement plants, Stranded gas fields and oil refineries and most CO2 emitting industrial processes

EcoTechnol Gas Mitigation Process

Proprietary CO2 Capture and Microwave Assisted Dry Reforming Technology which separates CO2 from a range of gas streams to make clean fuels (synthetic fuels) via proven Fischer-Tropsch process.

Technology Well Developed

Other Benefits – Commercial and Environmental

- Capture and conversion of CO2 into ‘profitable products’

- Lower Capex and Opex costs verses conventional GTL technologies

- Uses the CO2 – which mitigates greenhouse gas emissions

- Can be retrofitted to existing fossil fuel plants – no need to replace existing infrastructure

- Suitable for small, medium and large production plants

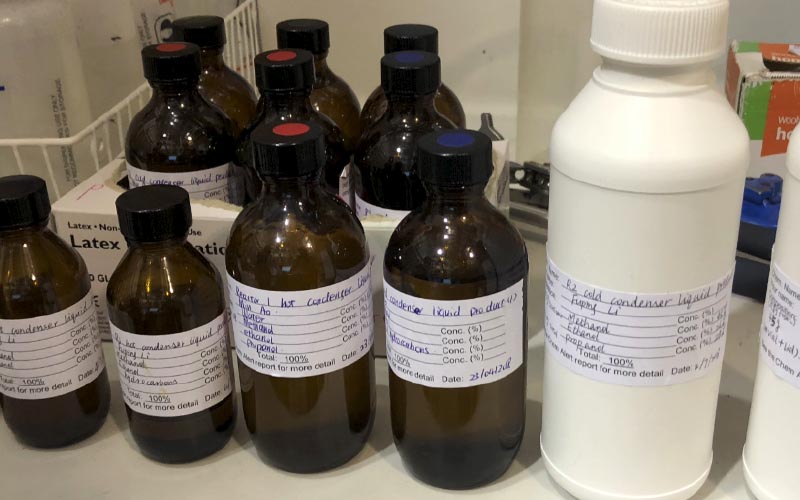

Liquid Fuel Production Test Rig-Lab2

- Curtin University – Fischer-Tropsch-GTL Plant

- Synthetic Liquid Fuels – produced from Ecotechnol Process

- Curtin University-developed the bi-metallic CoMo/TiO2 catalyst and using the microwave reactor (MW irradiation) for both DRM and SDR reactions (patent pending).