LITHIUM PROCESSING

Mining – Lithium Extraction and Processing

The rise of newer technologies such as lithium ion batteries, have not surprisingly, resulted in an increased demand for supplies of lithium. Lithium extraction using Ecotechnol’s proprietary acid membrane processes, can recover lithium from a variety of sources, in an environmentally responsible way.

Salar brine deposits – The process of lithium recovery initially involves extraction of lithium from salar brine deposits. Once extracted, Ecotechnol offers an effective process for recovery. Salar deposits are pre-treated to remove contaminants, and undergo chemical treatment processes, resulting in the separation of various elements. These elements are then filtered and processed in order to recover valuable lithium resources.

Clays (hectorite) – Ecotechnol can develop solutions to extract value adding materials such as lithium, from clay deposits. We apply various advanced technologies based on acid, alkaline, chloride, and sulphate leaching.

Hard rock – Hard rock can often yield substantial lithium deposits. Ecotechnol can develop a satisfactory solution to assist in the recovery of these resources. The extracted material is treated, filtered, and concentrated ready for re use or resale. Any associated wastewater undergoes a decontamination process, and where possible, is prepared for recycling and reuse.

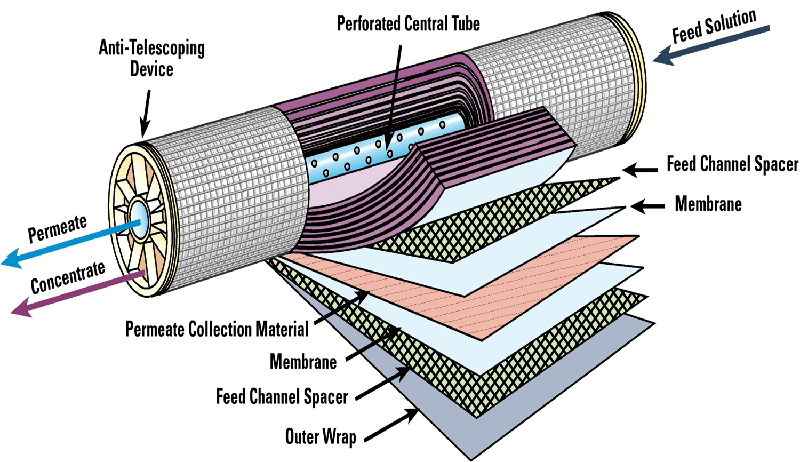

Ecotechnol Membrane Technology

Using Ecotechnol’s patented acid membrane processes, lithium can be recovered from a variety of mining environments.

Application of Modified Nanofiltration in the Lithium/Potassium Brine Process

Our advanced modified nanofiltration systems can be deployed with excellent results, enabling the successful separation and recovery of lithium/potassium from brine.

Lithium Battery Reclamation using Advanced Membrane Technologies

Ecotechnol uses advanced membrane technologies to recover lithium from batteries. We tailor the process of lithium recovery dependent on battery chemistry, and the scale and volume of recovery needed. Our technologies use proven chemical processes currently deployed in battery manufacturing, and the mining industry.

Ecotechnol’s lithium recovery solutions offer a range of benefits to industry and enterprises wishing to add value, lower their operating costs, and play an important part in recycling and enhancing the environment.

Our advanced technology offers many advantages:

- It is an environmentally conscious, closed loop process.

- It is also a highly efficient process capable of recovering 95%+ lithium, precipitated as lithium carbonate, or further processed to produce lithium hydroxide.

- A viable value adding process which can precipitate all other metals such as CO, Mg, Cu, These can then be sent for further refinement.

- It is a process that can recover most reagents, such as acid and water, which allows for reuse, as well as a reduction in process operating costs.

- All reagents are easily sourced, non-exotic, and low cost.