MEMBRANE TECHNOLOGY

How our powerful patented systems make it all happen

With over thirty years’ experience in utilising membrane technology in the nuclear and minerals industry, Ecotechnol have developed a highly specialised carbon capture process.

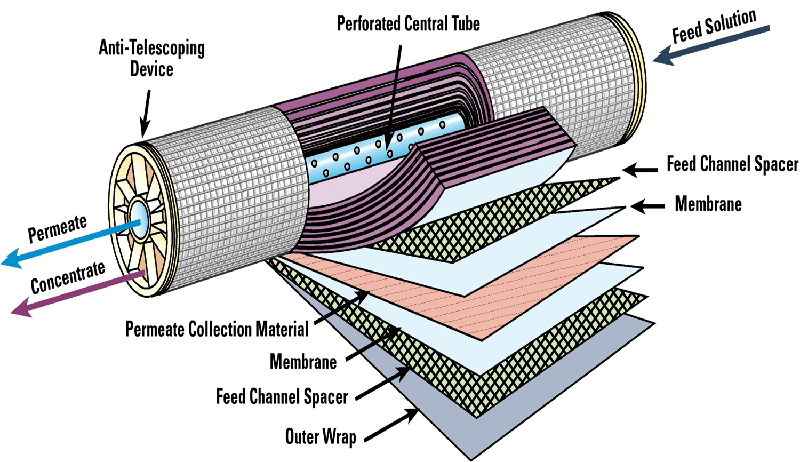

Our unique process uses a membrane element that effectively separates and concentrates CO2 from waste gas emissions. Through subsequent gas mitigation processes, CO2 is recycled, and converted into environmentally conscious clean fuels, and other value adding commodities.

Putting our innovative membrane technology to work

The Ecotechnol patented CO2 capture membrane system is compact and simple to operate, and provides a reduced carbon footprint, whilst adding substantial value.

We also have specialised membrane systems that can provide solutions for the mining and minerals sector including:

Solutions for the Mining and Minerals Sector

- The separation and recovery of valuable metals from large volume leach mining solutions (copper, zinc, iron, nickel, gold or silver).

- Cyanide recovery process

- Acid recovery and purification – Sulfuric/Hydrochloric/Hydrofluoric/Nitric/Phosphoric

- Alkaline recovery and purification – Caustic/Potassium Hydroxide/Cyanide

- Recovery and purification of waste water, and the production of potable water

- Removal of process contaminants, and concentration of metals to improve process yields

- An effluent treatment process for the recovery of metals, and reagents for reuse

How can we assist your industry?

All of our specialised membrane systems consider cost effectiveness and environmental impact, as well as the requirement for industry to meet current environmental standards. In addition, they are constructed to be durable, and in many cases, transportable, and are easily retrofitted to pre-existing plant or mining infrastructure.

Simplicity is often the key to finding the best solutions to the most complex problems. We ensure that our systems are designed efficiently, require low ongoing operating and maintenance costs, and are kept as simple to operate as possible.

Membrane Applications for Mineral Processing

Ecotechnol’s membrane technology offers unique separation techniques which assists the mineral processing industry with:

- Recovery of metals (some profitable)

- Recovery of acids or caustic for re-use

- Reduction of disposal costs

- Environmental applications

- Socially responsible processing

An Overview with Case Studies

Ecotechnol’s specialised membranes have been developed and manufactured to withstand the harshest and most challenging mineral processing environments. All skids have integral automatic cleaning with remote monitoring systems available.

We have designed, developed and installed a variety of mineral processing systems globally and we take pride in building quality systems that are durable and efficient.

Reference List Membrane Installations and Experience

|

Project |

Description |

Flowrate (m3/hr) |

Year |

|---|---|---|---|

|

Barrick Gold Mine Barren-Lagunas Norte & Pierina |

Barren leach post physical chemical treatment installation |

910 |

2013 |

|

Cobre Las Crucas Sevilla – Spain |

ARD MDS with Spanish partner |

600 |

2011 |

|

Phelps-Dodge (Freeport-McMoran) – Texas |

Acid Purification with NF & Concentration: RO |

40 |

1992 |

|

Zijin Copper – China |

ARD (acid rock drainage) |

250 |

2009 |

|

Sun Metals Zinc Refinery – Australia |

Post physical chemical high pH |

250 |

1999 |

|

Korea Zinc Refinery – Korea |

Post physical chemical |

200 |

2001 |

|

Newmont Waihi Gold – New Zealand |

HWP Technologies |

250 |

2008 |

|

Asarco Refinery – Denver |

MDS Membranes & HWPT |

20 |

1995 |

|

Yanacocha Gold Mine |

Barren Leach |

3500 |

2003 |

|

Phelps-Dodge (Freeport-McMoran) |

Acid rock drainage |

150 |

2003 |

|

Cananea de Mexicana |

Acid rock drainage |

2000 |

1997 |

|

Kennecott Copper – Utah |

Acid rock drainage |

500 |

1998 |

Ecotechnol NF treatment of hypersaline water

- Aim: to concentrate Magnesium (Mg2+) via NF

- Reason: To reduce the buffering effect of hypsersaline water, reducing lime & cyanide consumption

- Location: Incoming bore water and/or return decant water

- >95% rejection of Mg2+, > 98% rejection of SO42- into 10-20% volume

- ~80-90% reduction in lime consumption, ~30% reduction in cyanide

- Concentration of gypsum thus reducing scale potential within the process plant

- TDS a 1/Volumentric recovery

- Membranes remove the ions in hypersaline water responsible for high reagent consumption

- Acid/Caustic purification and Environmental Applications (AMD, metals)

- Replace SX prior to Electrowinning OR pretreatment prior to SART Copper

- High rejection of magnesium, calcium and sulphate

- Significant reduction in lime consumption and ability to increase pH reducing cyanide consumption

Improving Gold Mining Economics Through The Use Of Membrane Technology

We can assist with the following processes, and develop tailored solutions to improve cost effectiveness, and production capacity.

- Reduction of lime and cyanide consumption at WA gold mines

- Copper Rejection & Gold Transmission

- Modified Loose RO – Caustic Stable Membranes

Ecotechnol has substantial expertise and experience in the design, development and application of a range of membrane technologies. We aim to create systems, processes, and treatment plants which improve process yields and operating profits, as well as responsibly lowering the environmental impact of refinery operations.

Membrane technologies have the potential to add value to processing fluids produced by refineries during their regular operations. Our expert technology allows for efficient treatment processes such as separating metals from acids, or concentrating acids and producing high quality process fluids. The unique selectivity of membranes, enables the production of purified acid, or purified high pH cyanide solution free of metal impurities.

Environmental applications of membrane technology range from treating Acid Mine Drainage (AMD), to cost effectively comply with surface discharge standards. Our membrane technology can also assist in the management and treatment of process plant wastewater in order to recover heavy metals and/or reagents. This technology also permits the production of clean, decontaminated water which can be safely discharged to the environment.

Hydrometallurgical applications for mining and refinery processes

- Purify, fractionate or concentrate gold, copper, sinc, nickel, uranium or silver

- Treatment of slurries containing up to 60 wt% solids

- Separate materials from large volume leach mining solutions containing Cu, Zn, Fe, Ni, Au, Ag

- Treatment Acid Mine Drainage (AMD)

- Cyanide Recovery Process

- Spent Acid Recovery – separate and recover leach acid from hydrometallurgical operations

- Metals Recovery (Cu, Ni, Zn, etc) from sensitive waste streams to environmental discharge regulations

- Caustic Recovery – recover caustic and sodium aluminate from Bayer process streams

- Acid Recovery and Purifcation – Sulfuric/Hydrochloric/Hydrofluoric/Nitric/Phosphoric

- Alkaline Recovery and Purification – Caustic/Potassium Hydroxide/Cyanide

- Water balance management, including recovery and purification of water for reuse

- Nickel Metal Hydride Battery Reclamation

Ask us to develop a cost effective, and comprehensive eco-friendly solution that meets your needs

Our wide ranging knowledge, proficiency, and applied technology, can help industry achieve a multitude of important business and operational objectives.

Other advisory services we offer:

- Achieving environmental and economic best practice: Gold mining

- Gold Process Plants, Operational Savings & Gold Recovery

- Acid & Alkaline membrane applications in mining

- Reference plants & operating data & analyses

- RO and NF membranes run on high concentrations of various mineral & organic acids

- Removal of ammonia and other impurities from process waters by membrane separation

- Membrane based hydrometallurgical process for fractionation of high copper content from gold in pregnant leach solutions coupled with copper and cyanide recovery using SART process

Membranes and SART

- Smaller SART Plant requirements (lower OPEX through reagent reductions)

- Higher efficiencies with higher incoming copper tenures

- Improved Electrowinning of AU through prior Cu removal

The Use of Nanofiltration in Process Plants

Ecotechnol specialize in designing and implementing a broad range of modified nanofiltration (NF) membrane technologies for a range of industries and applications. We are able to provide:

- Containerised and modular systems – turnkey installations

- NF systems that effectively separate polyvalent ions from monovalent ions (no chemicals required)

- NF systems that are modified reverse osmosis plants utilizing our specially designed membranes

- NF systems that reduce power costs by operating at significantly lower operating pressures than reverse osmosis